Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Our prototype construction services

A BIG PLUS IN PROTOTYPING: ADDITIVE MANUFACTURING.

Prototype construction with various 3D printing processes offers an efficient and flexible method for producing prototypes. It enables designs to be validated more quickly, specific requirements to be adjusted and functionality to be tested.

SELECTIVE LASER SINTERING (SLS)

The piece de resistance of 3D printing.

Selective laser sintering is a generative layer-building process and enables you to instantly obtain functioning plastic prototypes that are ready for use. The highly efficient and resource-saving process delivers prototypes in record time.

SLS parts being unpacked from the build chamber.

METAL LASER SINTERING (MLS)

Your ideas in delicate metal structures.

Metal laser sintering is a special rapid prototyping process used to manufacture metal parts. This process offers impressive flexibility that enables even the most complex geometries to be produced with high quality and minimal resources. Due to their good load-bearing capacity, metal laser sintered parts are an excellent choice for use as functional prototypes.

Delicate stainless steel and copper structures.

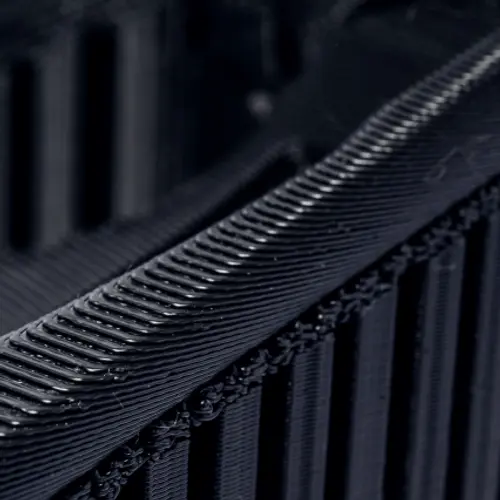

FUSED DEPOSITION MODELING (FDM)

Printed, robust and strong standard materials.

Fused deposition modelling enables high precision with complex geometries and fine details. The process is suitable for materials with low melting points and low thermal conductivity. It is cost effective and enables rapid iteration and adjustment of prototypes.

Section of a headrest produced with the FDM process.

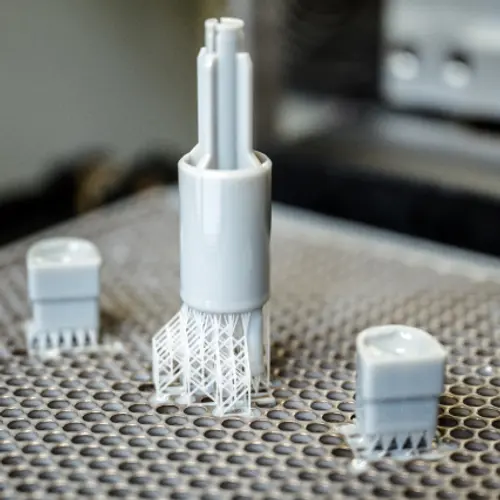

STEREOLITHOGRAPHY (SLA, DLP)

High precision for manufacturing complex components.

Stereolithography is a high-precision 3D printing process based on photopolymerisation. It is often used to produce detailed prototypes, functional components and high-quality end products. SLA printing enables extraordinarily accurate details and smooth finishes. Perfect for reproducing prints with hollow spaces or complex geometries.

Finished SLA component with support structure.

VACUUM CASTING (PU)

Duplication at its best.

Vacuum casting is a duplication process that enables high-quality polyurethane (PU) parts to be produced with excellent precision in minimal time. We offer a wide range of polyurethanes so that we can cater for any customer requirements.

Reflector lenses produced with vacuum casting.

POLYAMIDE CASTING (PA)

High-performance components with impressive properties.

Polyamide casting is an innovative production process that can be used for a wide range of polyamide materials with special properties such as strength, flexibility, heat resistance and chemical resistance. The cast polyamide parts have smooth surfaces and highly accurate details. There is generally no need for finishing work such as polishing or painting.

Fan wheel produced with polyamide casting.

Our case studies

MODELLTECHNIK IN ACTION

Automotive

A body with class: We produced the master model for the body of the cult Evetta light electric vehicle on a 1:1 scale – with perfect milling and the finest surface finishing. Find out how.

Industry

The socket for the forest: We developed the prototypes for a type of powerbank for Stihl, which was put through its paces by forestry workers. A truly powerful project.

Aerospace

"Jena, we have no problem": Jena-Optronik commissioned MODELLTECHNIK to produce a 1:1 model of the Gateway Docking Port, which is needed for sensor tests in space applications.

Design

Timeless and dignified: Working with Samosa and our expertise in 3D printing, MODELLTECHNIK creates beautiful templates and design samples for individually designed funeral urns.

Contact us

Whether you’ve got technical, commercial or specialist questions – we’re here to help.

START A QUERY NOW„Spot-on delivery under extreme time pressure [...] It couldn't be more perfect“

„Spot-on delivery under extreme time pressure [...] It couldn't be more perfect“