Efficiency

Standardisation of processes and procedures

Sustainability

Energy management systems, carbon footprint reduction

Quality

Certifications

Mobility

Optical measurement at the customer’s site

Optimisation

Continuous improvement process

Knowledge

Staff training

Efficiency

Standardisation of processes and procedures

Sustainability

Energy management systems, carbon footprint reduction

Quality

Certifications

Mobility

Optical measurement at the customer’s site

Optimisation

Continuous improvement process

Knowledge

Staff training

Our quality management services.

TOP QUALITY IS THE TOP PRIORITY.

Our quality management ensures that we always meet your and our expectations – and even exceed them. From the idea to implementation and the finished product.

CERTIFICATION

Verified expertise that creates confidence.

In addition to the standard requirements for quality management systems with DIN EN ISO 9001:2015, MODELLTECHNIK has further certifications with IATF 16949:2016 and TISAX certification for confidential data exchange with our customers. We have an established quality management system that has been certified since 1997.

As sustainability and reducing CO2 emissions are also very important at MODELLTECHNIK, we expanded the management system with DIN EN ISO 14001:2015 and DIN EN ISO 50001:2018 certifications in 2022.

English text required

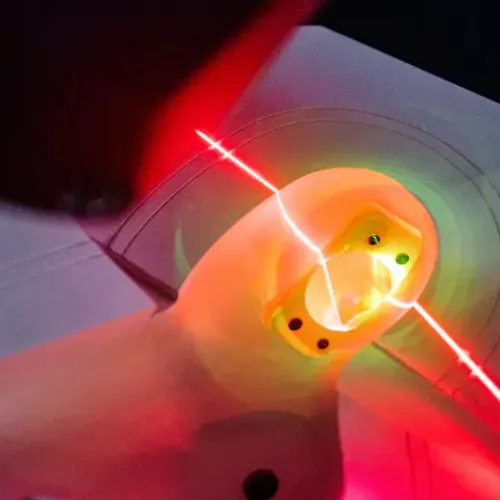

MEASUREMENT TECHNOLOGY

New standards for the quality you expect.

Modern measurement technology and proven manual testing methods are part of our manufacturing team’s day-to-day work. If required, we can support our customers as a service provider for measurement technology – in the automotive and non-automotive sectors. We monitor series production processes and produce statistical trend analyses for the products we supply. Our mobile optical measurement technology enables us to measure tools, equipment or components at the customer’s site.

English text required

QUALITY ASSURANCE

A core component of our daily work.

As part of quality management, we deal with organisational and technical measures throughout the process chain. These are needed for preparation, support and testing to guarantee customer requirements. The degree of customer conformity is determined with target/actual comparisons. Our analytical working method is based on the PDCA cycle.

Our complaint management team plans and monitors the implementation of all measures on faulty products and equipment to ensure that we restore customer satisfaction. In doing so, MODELLTECHNIK follows the zero defect strategy.

— FMEA creation

— Test equipment planning

— Test equipment management

Test plan creation

— Sampling

— IMDS

— System audits

— Product and process audits

— Potential analysis

— Supplier evaluation

— Requalification

— Complaint management

Universelles Einstell- und Messgerät mit integriertem Werkzeugschrumpfsystem.

FAQ - Quality management

Interesting facts about quality management

- 1. What is quality management? - Simply explained

Quality Management is a systematic approach that enables companies to ensure their products or services consistently meet customer requirements and comply with legal regulations. It encompasses all processes and measures aimed at preventing errors, adhering to standards, and continuously improving efficiency. Simply put, quality management ensures that products meet the highest standards and customer expectations from development to delivery.

For companies like MODELLTECHNIK, quality management is particularly crucial, as prototyping and mold construction require extremely precise and often one-of-a-kind manufacturing. This involves aligning all steps, from material selection and production techniques to final inspection, with the utmost precision and error-free execution. Each step of the manufacturing process is monitored and documented to ensure maximum transparency and reliability.

Tasks in Quality Management and what it stands for

The tasks in quality management are diverse and encompass all activities that contribute to ensuring product and process quality. The key responsibilities of quality management include:

- Planning: Defining quality standards and specific criteria for each product or process. These standards are based on customer requirements and industry-specific norms.

- Monitoring and Testing: Ongoing oversight of all production steps through precise measurements, tests, and inspections to ensure compliance with specifications.

- Error Detection and Correction: Identifying and analyzing errors and implementing immediate actions to eliminate the sources of errors. The focus here is not just on addressing issues but on sustainably eliminating their root causes.

- Employee Training: Ensuring all employees are familiar with and can apply quality standards. Skilled employees are the foundation for consistently high product quality.

- Continuous Improvement: Regularly reviewing and optimizing all processes according to the CIP (Continuous Improvement Process) principle. This forms the basis for sustained efficiency improvements and innovation within the company.

MODELLTECHNIK relies on a comprehensive quality management system that places customer requirements at the center and ensures all products meet the highest standards through continuous monitoring and improvements. This holistic approach guarantees not only consistent product quality but also a high level of customer focus and efficiency in production processes.

- 2. Important standards: DIN ISO 9001:2015, IATF 16949:2016, DIN EN ISO 14001:2015 and DIN EN ISO 50001:2018

In industrial manufacturing, particularly in prototyping, certifications play a central role. These standards ensure that companies achieve and maintain globally comparable and uniformly regulated quality levels. The most important standards include:

- DIN ISO 9001:2015: This standard forms the foundation for quality management systems worldwide. It specifies how processes must be designed to consistently meet high-quality standards. DIN ISO 9001:2015 is particularly focused on understanding and fulfilling customer requirements.

- IATF 16949:2016: Tailored to the automotive industry, this standard addresses the stringent requirements of vehicle manufacturing and supply. It complements ISO 9001 and sets even higher benchmarks for quality processes, error prevention, and risk minimization during production.

- DIN EN ISO 14001:2015: This is the international standard for environmental management. It defines how companies can reduce environmental impacts and make their processes more sustainable. At MODELLTECHNIK, this standard ensures a focus on sustainability alongside quality in production.

- DIN EN ISO 50001:2018: This energy management standard helps companies improve energy efficiency and conserve resources through responsible energy use. This is particularly important in prototyping, which often involves energy-intensive processes.

By implementing these standards, MODELLTECHNIK ensures that customers can rely on seamless quality assurance. For customers, this means not only products manufactured with the highest precision but also production practices that are environmentally responsible and energy-efficient.

- 3. What are the advantages of quality management for MODELLTECHNIK customers?

Safety and Reliability Through Certified Processes

With certifications such as ISO 9001 and IATF 16949, MODELLTECHNIK ensures a high level of process security and reliability. Customers benefit from clearly defined workflows that guarantee prototypes and small series are manufactured consistently and to the highest quality standards. For businesses, this translates into increased dependability and seamless collaboration, especially in regulated industries such as the automotive sector.

Environmental Awareness and Energy Efficiency

By complying with ISO 14001 and ISO 50001, MODELLTECHNIK meets stringent environmental and energy standards, ensuring sustainable and resource-efficient production. Customers can trust that MODELLTECHNIK not only delivers precise products but also operates responsibly—an advantage particularly valued by companies focused on sustainability.

Flexibility and Adaptability for SMEs

Thanks to a flexible quality management system, MODELLTECHNIK can cater to the individual requirements of small and medium-sized enterprises (SMEs). Standardized processes enable quick adjustments and high efficiency, even for small production runs. Customers benefit from rapid response times and services tailored to specific project needs.

- 4. Key questions about quality management answered

What does quality management involve?

Quality management encompasses all processes that ensure and improve product quality—from planning and implementation to monitoring and control. This includes quality standards like ISO 9001 and measures for continuous optimization.

What are the tasks of quality management?

The main tasks of quality management are:

- Setting standards,

- Monitoring compliance,

- Driving continuous improvement.

The goal is to identify potential sources of errors early, improve efficiency, and enhance customer satisfaction.

What is quality management?

Quality management is a structured system designed to ensure that products meet customer requirements and comply with legal regulations. It provides a foundation for consistently high quality and competitive advantages.

What is the goal of quality management?

The goal of quality management is to ensure consistently high product quality with maximum efficiency. This involves conserving resources, avoiding errors, and increasing customer satisfaction.

What does quality management mean for customers?

For customers, quality management at MODELLTECHNIK ensures a high level of safety and reliability. Certified processes deliver products that are precisely manufactured and sustainably produced—key advantages for demanding projects.

Choose uncompromising quality!

Whether precise prototypes, durable tools, or tailored small series, MODELLTECHNIK is your reliable partner. Discover how certified processes and the highest quality standards can ensure your project’s success. Let’s take the next step together—contact us and benefit from our expertise!

Our case studies

MODELLTECHNIK IN ACTION

Automotive

A body with class: We produced the master model for the body of the cult Evetta light electric vehicle on a 1:1 scale – with perfect milling and the finest surface finishing. Find out how.

Industry

The socket for the forest: We developed the prototypes for a type of powerbank for Stihl, which was put through its paces by forestry workers. A truly powerful project.

Aerospace

"Jena, we have no problem": Jena-Optronik commissioned MODELLTECHNIK to produce a 1:1 model of the Gateway Docking Port, which is needed for sensor tests in space applications.

Design

Timeless and dignified: Working with Samosa and our expertise in 3D printing, MODELLTECHNIK creates beautiful templates and design samples for individually designed funeral urns.

Contact us

Whether you’ve got technical, commercial or specialist questions – we’re here to help.

START A QUERY NOW„The lifeblood of MODELLTECHNIK is in every prototype. You can feel that in the collaboration and in the results.“

„The lifeblood of MODELLTECHNIK is in every prototype. You can feel that in the collaboration and in the results.“