Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Our technical consulting services

ADVICE IS ALL ABOUT KNOWLEDGE.

Plastic components have become an integral part of our world. We provide our customers with innovative solutions for their requirements and are always there to help with our expertise.

COMPONENT DESIGN AND DEVELOPMENT

A symbiosis of state-of-the-art software and human expertise.

Our consultancy services start right from the design phase to help create components that are tailored to the plastics and tools. This enables us to achieve quality standards against a backdrop of efficiency improvements to strengthen our customers’ competitiveness.

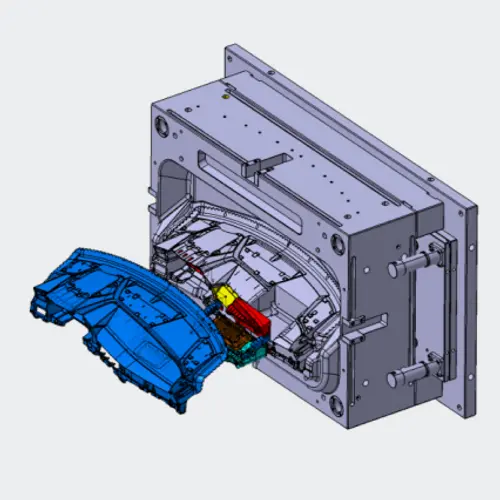

Visualisation of an injection moulding tool for an instrument panel.

FILLING SIMULATION AND WARPAGE CALCULATIONS

Three-dimensional details for high-quality production.

Filling simulations and warpage calculations simulate the flow of plastic in a mould. This means that injection points and process parameters can be optimised and component weaknesses can be identified at an early stage. Warpage simulation is often particularly necessary for complex parts with fibre reinforcement as a large degree of distortion will mean that the component needs to be changed.

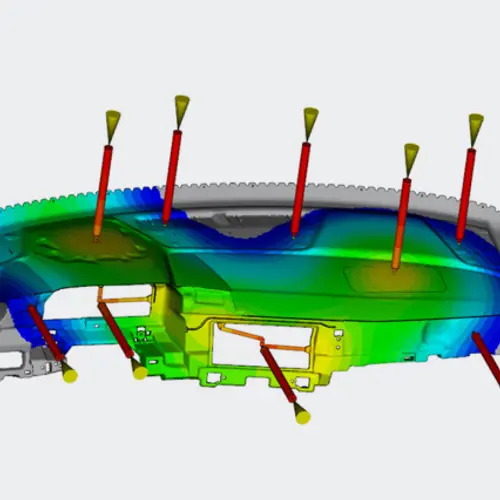

Filling simulation for an instrument panel bracket.

CAD-based warpage compensation

Effectively counteracting distortion.

The geometry and material of a component can have a big impact on its dimensional accuracy. With large components, differing wall thicknesses or a lack of supporting structures, this can sometimes lead to undesired deformation. As there are limited options to counteract this by adjusting the process parameters, adapting the component’s shape offers a way to compensate for this warping. The information obtained from the filling and warpage calculation helps to adapt the CAD data to act against the direction of deformation.

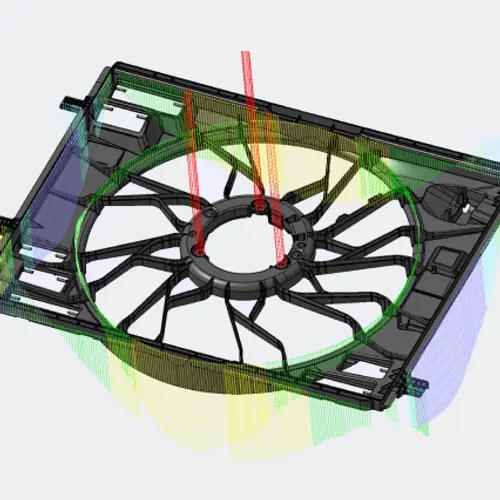

Warpage compensation calculation of a distortion-prone component.

Our case studies

MODELLTECHNIK IN ACTION

Automotive

A body with class: We produced the master model for the body of the cult Evetta light electric vehicle on a 1:1 scale – with perfect milling and the finest surface finishing. Find out how.

Industry

The socket for the forest: We developed the prototypes for a type of powerbank for Stihl, which was put through its paces by forestry workers. A truly powerful project.

Aerospace

"Jena, we have no problem": Jena-Optronik commissioned MODELLTECHNIK to produce a 1:1 model of the Gateway Docking Port, which is needed for sensor tests in space applications.

Design

Timeless and dignified: Working with Samosa and our expertise in 3D printing, MODELLTECHNIK creates beautiful templates and design samples for individually designed funeral urns.

Contact us

Whether you’ve got technical, commercial or specialist questions – we’re here to help.

START A QUERY NOW„Spot-on delivery under extreme time pressure [...] It couldn't be more perfect“

„Spot-on delivery under extreme time pressure [...] It couldn't be more perfect“