Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Our gauge construction services.

PRECISION IS WHEN EVERYTHING IS AS IT SHOULD BE.

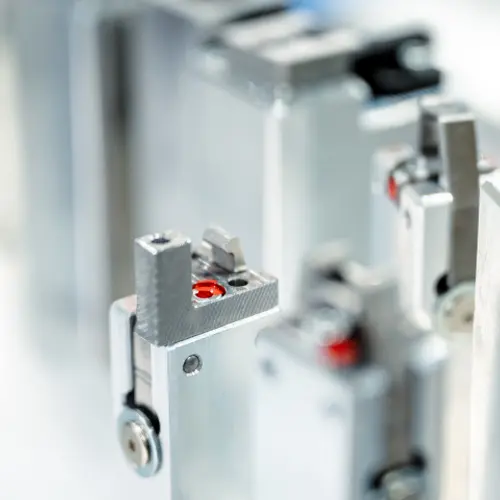

We take it particularly seriously when it comes to gauge construction. So you can rely on absolute precision with all our products and services.

SERVICES

Step by step to the perfect result.

Our experts perform each individual step in gauge construction with the greatest care and precision to guarantee you the best possible quality. We offer you personal and comprehensive advice – from the specifications for your enquiry through to validation – and make sure that any questions are answered. Just get in touch!

Our expertise for excellent measurement and testing results.

PRODUCTS

Unique solutions, endless possibilities.

We supply our products to well-known OEMs and large system suppliers. You can find a detailed insight into our product range here.

Tailor-made solutions for precise results.

FAQ - Gauge Construction

Interesting facts about Gauge Construction

- 1. What is gauge building and when is it used?

Gauge construction is an essential part of industrial manufacturing and metrology. Jigs serve as inspection tools that help verify workpieces and components for their dimensional accuracy, shape, and functionality. They ensure that a component meets specified tolerances without requiring a complicated, comprehensive measurement in the measurement room.

Definition and Basics of Gauge Construction

Gauges are essentially devices designed to detect dimensional deviations in gauges that directly check length measurements or form gauges that ensure compliance with geometric shapes. The use of jigs is particularly important in mass production, where rapid and efficient inspections must occur to avoid interrupting the production process. The gauge construction at MODELLTECHNIK is distinguished by a high degree of precision and the use of modern technologies. With decades of experience, MODELLTECHNIK is capable of offering tailored solutions for various industries, from the automotive sector to medical technology. Sven Meinschein, head of gauge construction at MODELLTECHNIK, describes gauge construction as a critical process that helps relieve the capacities of the measurement room while enabling continuous quality control directly in manufacturing.

Gauges in Metrology: Important Functions and Applications

Gauges are used wherever components require precise dimensional accuracy. They allow for direct sampling checks during the production process without burdening the measurement room. This not only shortens throughput times but also ensures that potential manufacturing errors are detected early. Typical applications for gauges can be found in the automotive industry, where they are used to inspect body parts, door panels, or dashboards. They are also frequently used in medical technology or mechanical engineering to ensure that highly precise components such as dental devices or sensors are manufactured accurately.

- 2. What gauges and test equipment are available?

Examples of Gauges and Inspection Tools

Gauges and inspection tools are indispensable instruments in manufacturing to ensure the quality of components. Their main task is to check compliance with specified dimensions and tolerances. In practice, there are a variety of gauges tailored to different inspection requirements.

Dimensioning Gauges and Inspection Gauges: Precise Solutions for Different Needs

Dimensioning gauges are classic inspection tools used to control lengths or diameters. A typical example is end standards, which enable highly precise distance measurements. They are particularly sought after in mass production due to their ability to facilitate quick and straightforward measurements.

Inspection gauges, on the other hand, are used to verify more complex shapes and geometries. They are particularly applied when not only individual measurements matter, but also the interplay of multiple dimensions and shapes. Examples include fitting jigs, which ensure that components fit together perfectly, or contour gauges, which check compliance with specific surface contours.

A typical example from the gauge construction at MODELLTECHNIK is the manufacturing of inspection tools for the automotive industry. Here, jigs are produced to check body parts, such as door panels or center consoles, for dimensional accuracy and fit. These jigs are essential to ensure that components can be seamlessly integrated into the overall system of a vehicle.

- 3. Which materials and technologies are used in gauge construction?

Modern gauge construction benefits from advanced technologies and a broad range of materials tailored specifically to the needs of various industries and applications. Whether in the automotive, aerospace, or medical sector, choosing the right materials and manufacturing techniques is crucial for producing gauges and inspection tools that are durable, precise, and efficient in use.

Materials Used: Aluminum, Steel, Ureol®, and 3D Printing materials

Different materials are used in gauge manufacturing, depending on requirements for stability, precision, and cost. Some of the most commonly used materials include:

- Aluminum: With its lightweight and excellent machinability, aluminum is the preferred material for jigs that need to be both light and stable. It is ideal for large, complex components that need to be easy to handle.

- Steel: Stainless steel offers maximum precision and durability. It is used in applications where mechanical strength and resistance to wear are essential, such as in tool and mold construction.

- Ureol®: This specialized plastic is often used for prototypes and gauges subjected to less mechanical stress. Ureol® offers flexibility in shaping and is ideal for short-term, cost-effective solutions.

- 3D Printing: Modern 3D printing technologies open up entirely new possibilities in gauge construction. With additive manufacturing, complex geometries can be realized quickly and with high precision. This is especially advantageous for prototypes or small series, as it does not require expensive tooling.

Modern Manufacturing Technologies: Efficiency and Precision Combined

By combining subtractive and additive manufacturing technologies, companies like MODELLTECHNIK can offer custom solutions for any need. Traditional processes like milling and turning enable the production of highly precise metal parts, while 3D printing supports the flexible manufacturing of plastic gauges. This variety of technologies ensures that both individual projects and larger series productions can be completed efficiently and cost-effectively.

The use of state-of-the-art technologies allows for significantly shorter lead times in gauge construction while maintaining the highest precision. This is particularly beneficial for industries that demand tight tolerances and high-quality standards for their components, such as the automotive and aerospace sectors.

- 4. What is the manufacturing process in gauge construction at MODELLTECHNIK?

Quality Assurance in Gauge Construction: Precise Measurement and Inspection

Quality assurance is essential in gauge construction to ensure that each inspection tool meets the highest standards. ModellTechnik relies on proven metrology methods to verify the accuracy of the gauges and inspection tools it produces, ensuring consistently high product quality.

Inspection Methods: Testing, Measuring, and Gauging

Various inspection methods are used in the gauge manufacturing process to verify that specified tolerances are met. These include both tactile and optical measurement methods that control the geometry and dimensional accuracy of the gauges. Modern measuring machines and inspection tools guarantee high precision in the quality control of components.

Another important method is the Measurement System Analysis (MSA), which assesses the ability of a measurement tool to provide reliable and reproducible results. These analyses are crucial to confirm that the gauges are suitable for daily production use and continue to deliver accurate results under repeated inspection conditions.

- 5. Which certifications does MODELLTECHNIK have?

MODELLTECHNIK is certified according to the international standards IATF 16949 and DIN ISO 9001. These certifications underscore the company’s high standards of quality and ensure that all internal processes and workflows are closely monitored and continuously improved. The IATF 16949 certification is particularly significant in the automotive industry, as it sets specific quality management requirements for the supply chain. ISO 9001, on the other hand, is a globally recognized standard for general quality management systems, ensuring that all products and services meet customer requirements.

At MODELLTECHNIK, we are committed to the highest precision and innovation to optimize your manufacturing processes. From design to final approval, we are your reliable partner every step of the way. Contact us today, and let’s develop the perfect solution for your requirements together!

Our case studies

MODELLTECHNIK IN ACTION

Automotive

A body with class: We produced the master model for the body of the cult Evetta light electric vehicle on a 1:1 scale – with perfect milling and the finest surface finishing. Find out how.

Industry

The socket for the forest: We developed the prototypes for a type of powerbank for Stihl, which was put through its paces by forestry workers. A truly powerful project.

Aerospace

"Jena, we have no problem": Jena-Optronik commissioned MODELLTECHNIK to produce a 1:1 model of the Gateway Docking Port, which is needed for sensor tests in space applications.

Design

Timeless and dignified: Working with Samosa and our expertise in 3D printing, MODELLTECHNIK creates beautiful templates and design samples for individually designed funeral urns.

Contact us

Whether you’ve got technical, commercial or specialist questions – we’re here to help.

START A QUERY NOW„The SLS models were found to be very good at today's customer presentation and received a lot of praise. The precise, detailed representation of the models with on-time delivery is particularly noteworthy. A reason to be happy and an incentive for further exciting projects.“

„The SLS models were found to be very good at today's customer presentation and received a lot of praise. The precise, detailed representation of the models with on-time delivery is particularly noteworthy. A reason to be happy and an incentive for further exciting projects.“