- PRECISION FOR SPACE

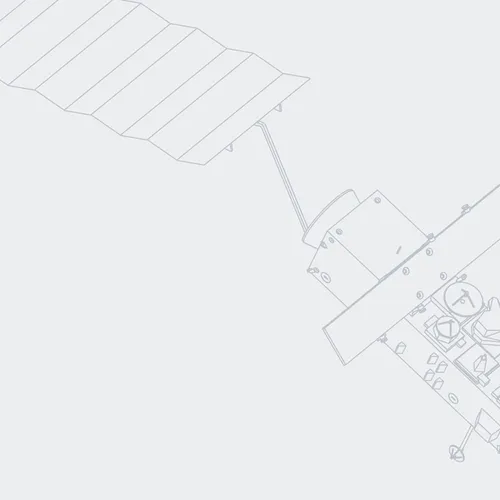

A 1:1 model of a docking port was needed for LiDAR sensor tests. MODELLTECHNIK was able to turn this exciting project into reality.

OUR TASKS

Concept and construction service as well as production of a mobile, transportable, demountable 1:1 model including transport trolley, frame and transport box with maximum precision and dimensions. Project management included.

METHODS AND TECHNOLOGIES USED

Support in product development

Manufacturing of components using additive manufacturing processes (SLS and MLS)

Milled parts including surface coating made of aluminum

Production of laminating tools including 3D printing inserts

Production of fiberglass laminates

Manufacture and customization of bent sheet metal parts

Surface finishing: painting, coating, foiling

Assembly of assemblies

Creation of operating and assembly instructions

Direct delivery with assembly workshop

Customer Benefits

Our customer received complete support from development to the on-site assembly workshop. Our many years of know-how from additive manufacturing, model and mold making came into play. For the mockup, SLS and aluminum parts were manufactured, a laminating tool including different GRP laminates was produced and the surface was finished according to customer specifications. Thank you very much for the pictures from Jena-Optronik GmbH from Mr. Christian Seeling.

258

Machine hours

183

Handwork hours

7

Manufacturing process

5

Materials

„The lifeblood of MODELLTECHNIK is in every prototype. You can feel that in the collaboration and in the results.“

„The lifeblood of MODELLTECHNIK is in every prototype. You can feel that in the collaboration and in the results.“

After just a month of coordination and preparation, production of the docking port mockup could begin. Jena-Optronik was therefore able to carry out the upcoming and necessary sensor tests optimally.

Contact us

Whether you’ve got technical, commercial or specialist questions – we’re here to help.

START A QUERY NOW„Product quality, speed and customer service speak for MODELLTECHNIK Rapid Prototyping“

„Product quality, speed and customer service speak for MODELLTECHNIK Rapid Prototyping“